The robotics race

Submitted by:

Sara Waddington

In the May 2023 issue of International Sheet Metal Review magazine, we examine the global market for industrial robotics and highlight investments, applications, key trends and benefits for users.

The global industrial robotics market was valued at US$ 26.52 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 10.5% from 2023 to 2030, according to analyst Grand View Research.

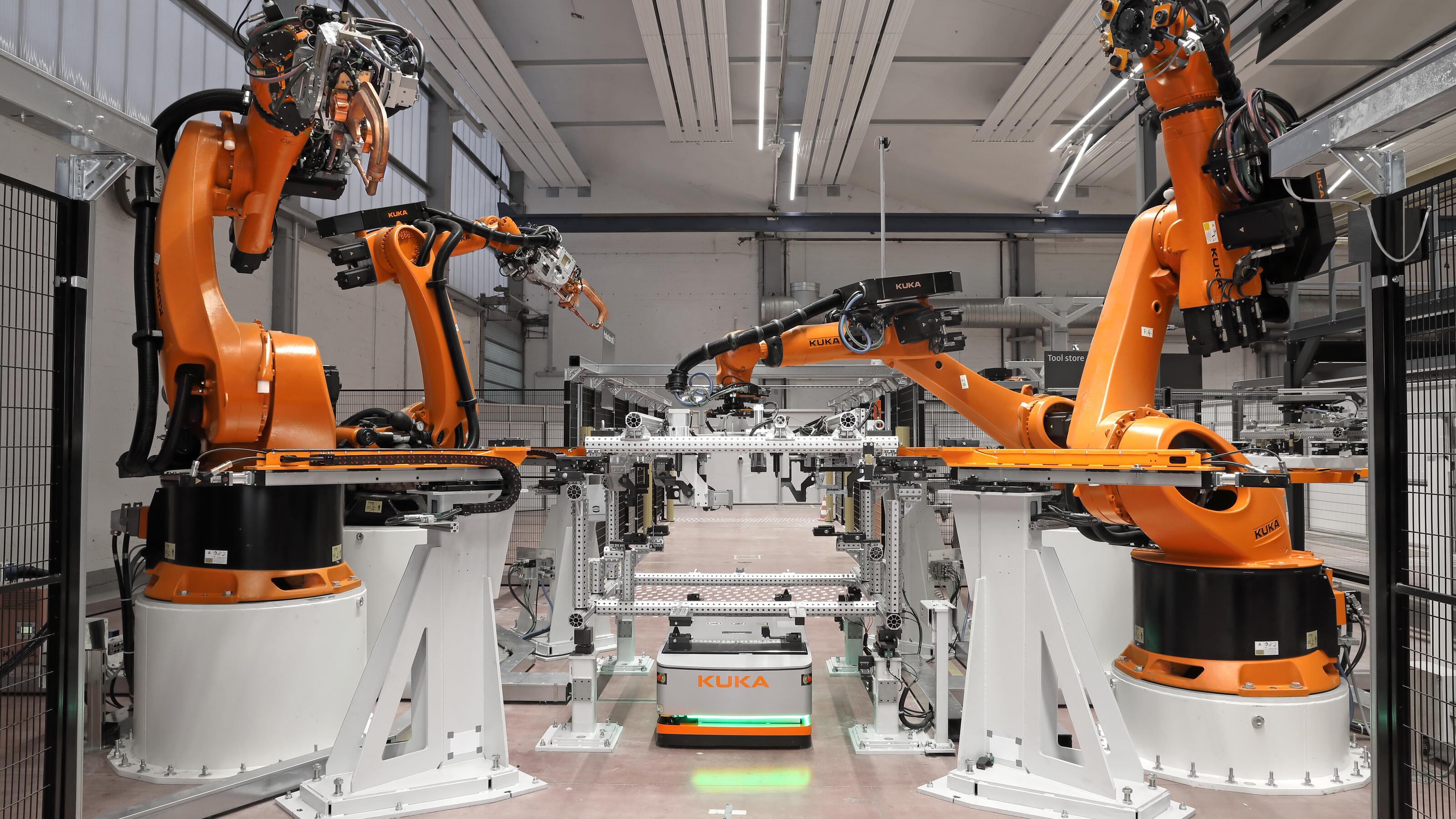

“The growing trend of Industry 4.0 is driving the use of robotics and smart manufacturing in the industrial sector. Manufacturers are expanding their factories to cater to the growing demand for industrial robotics,” said the market analyst.

“The rising trend of electric automobiles among new car owners remains promising, given the cost-benefit. It is expected to significantly impact the industrial robotics industry as car manufacturers have begun using automated robotic systems for the high-volume production of vehicles. The incorporation of machine learning and artificial intelligence technologies in industrial robots is positively influencing the business sector. The introduction of 5G technology is also expected to encourage the use of robotics in the manufacturing sector. The low latency of the 5G network allows instantaneous communication between systems for efficient coordination and connectivity,” it added.

Rising labour and factory insurance costs are expected to drive the introduction of industrial robotics for economical and effective resource allocation with minimal downtimes. The use of robotic systems significantly reduces the error rate, while simultaneously increasing the rate of output. Manufacturers are therefore integrating automated robotic systems to increase their operational efficiency and profit margins.

“The COVID-19 pandemic had a significant impact on the growth of the market. Following the COVID outbreak, there has been a rising demand for automated systems and robots which has created new opportunities in the market. Since the robots require minimal to no human input, the threat of potentially transmitting the virus remained low. In addition, industries doubled down on their automation plans for the future following the unforeseen shutdowns due to the pandemic, thus driving the market for industrial robotics,” added Grand View Research.

Applications and end uses

According to the analyst, the handling application segment dominated market share in 2022 while grossing more than 40% revenue share. The segment growth is attributed to the rising trend of e-commerce shopping and quick deliveries. Rapidly developing industries, such as automotive and electronics, use handling robots to move around small or heavy materials on the factory floor safely and expeditiously.

“The processing application segment is anticipated to grow at the fastest CAGR of over 20% over the forecast period from 2023 to 2030. The segment’s growth can be attributed to the minimal errors in their use in painting, cutting and other processes. These types of robots are gaining traction as they can operate around the clock owing to their set programming. Furthermore, robots can enter minute spaces and operate where human labour cannot, explained the analyst.

“The electrical/electronic end-use segment accounted for significant market share of over 25% in 2022. The segment dominated due to its ability to perform various tasks such as dispensing; insertion; labelling and screw driving, with high repeatability. The increased adoption of such industrial robots will be led by innovations coupled with rising research and development efforts by market players to improve productivity, cost-efficiency and low-manufacturing overheads. Increasing competition in the market with the emergence of various technology disruptors is expected to strengthen the segment outlook over the forecast period,” added Grand View Research.

Regional insights

The Asia Pacific region dominated the industrial robotics industry in 2022 and contributed toward a share of over 65%. The region is expected to dominate throughout the forecast period as well. Asia- Pacific region is home to many industries and factories which use industrial robots for manufacturing processes. The growing inclination towards automation, artificial intelligence and the evolution of other advanced technologies is providing significant growth potential for the regional market.

The Middle East & Africa region is anticipated to grow at the highest CAGR of over 20% during the forecast period, according to Grand View Research.

“The regional market growth is attributed to increasing industrial initiatives by government entities in the region. For instance, in September 2022, the crown prince of Dubai launched The Dubai Robotics and Automation Programme to boost robotics in the country. Under the programme, around 200,000 robots will be provided to industrial and logistics sectors to increase their production capabilities,” added the analyst.

Key players in the market use strategies (such as partnerships; acquisitions; ventures; innovations; R&D and geographical expansions) to solidify their industry position. Robotic manufacturers also focus on improving their product offerings to better suit the changing needs of users to stay competitive. Companies are also expanding their portfolios by launching new products or by significantly developing existing products.

Investment and demographic change

To read the rest of this article, see the May issue of International Sheet Metal Review magazine on https://joom.ag/Uw8d/p20