Porsche opens factory for all-electric Taycan

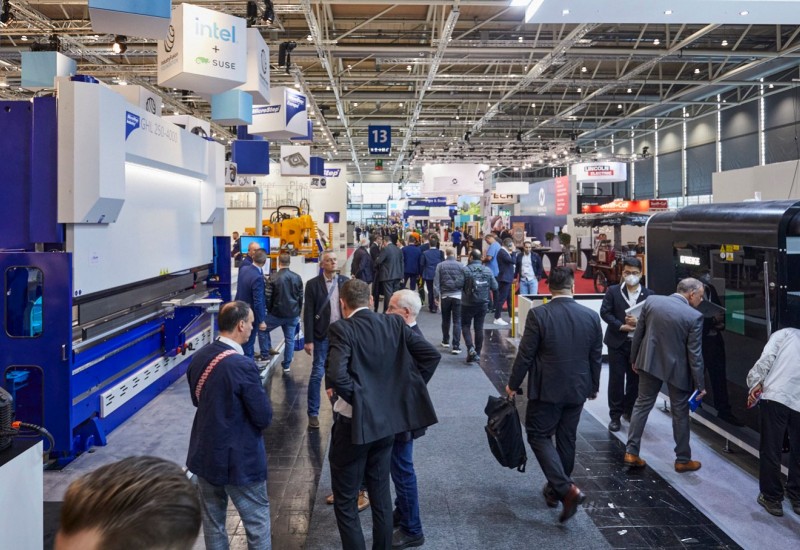

Header image: Factory opening for the Taycan in Stuttgart-Zuffenhausen.

Porsche has opened a new factory for the Taycan model under the watchful eye of 320 guests from politics, business and media. The automotive OEM is opening the next chapter in the company’s history with the brand’s first all-electric sports car and its bespoke production facility.

“The zero-emissions Taycan is a new Porsche icon,” said Oliver Blume, Chairman of the Executive Board of Porsche AG. “It is different to our previous vehicles, yet is still a typical Porsche – innovative, sporty and emotive.”

Less than 48 months have passed between the presentation of the Mission E concept vehicle at the IAA motor show in 2015 and the start of production for the first Taycan customer vehicles. The new production facility, said Porsche, sets new standards in terms of energy efficiency and environmental friendliness.

“We are committed to the climate protection targets agreed in Paris in December 2015 and have a clear responsibility to cut environmentally harmful emissions. However, our sustainability strategy goes much further than decarbonisation,” explained Albrecht Reimold, Member of the Executive Board for Production and Logistics of Porsche AG. “Porsche is pursuing the goal of a Zero Impact Factory – production without any negative impact on the environment.”

According to Porsche, the Taycan also heralds a new era in automotive production. Production is networked and flexible. Porsche uses automated guided vehicle systems instead of traditional conveyor belts to transport components and vehicles from station to station.

Production of the Porsche Taycan will see 1,500 new jobs created at the Zuffenhausen site, demonstrating that electromobility is generating employment at Porsche. While constructing the new factory and preparing for production, Porsche has also implemented a training programme to familiarise all employees with the unique features of electromobility.

In total, the company is set to invest more than six billion euros in electromobility by 2022. The company has invested a total of 700 million euros in the new production facilities alone, one billion including the new body shop, which will also be used for the current generation of the Porsche 911. The new factory complements production of two-seater sports cars – 250 vehicles from the 911 and 718 series roll off the assembly line every day at the Zuffenhausen site.

Subscribe to International Sheet Metal Review to receive 10 magazines per year, packed with the very latest industry news and product reviews.

Recent comments