Fluid cell presses for F&B Manufacturing

Submitted by:

Sara Waddington

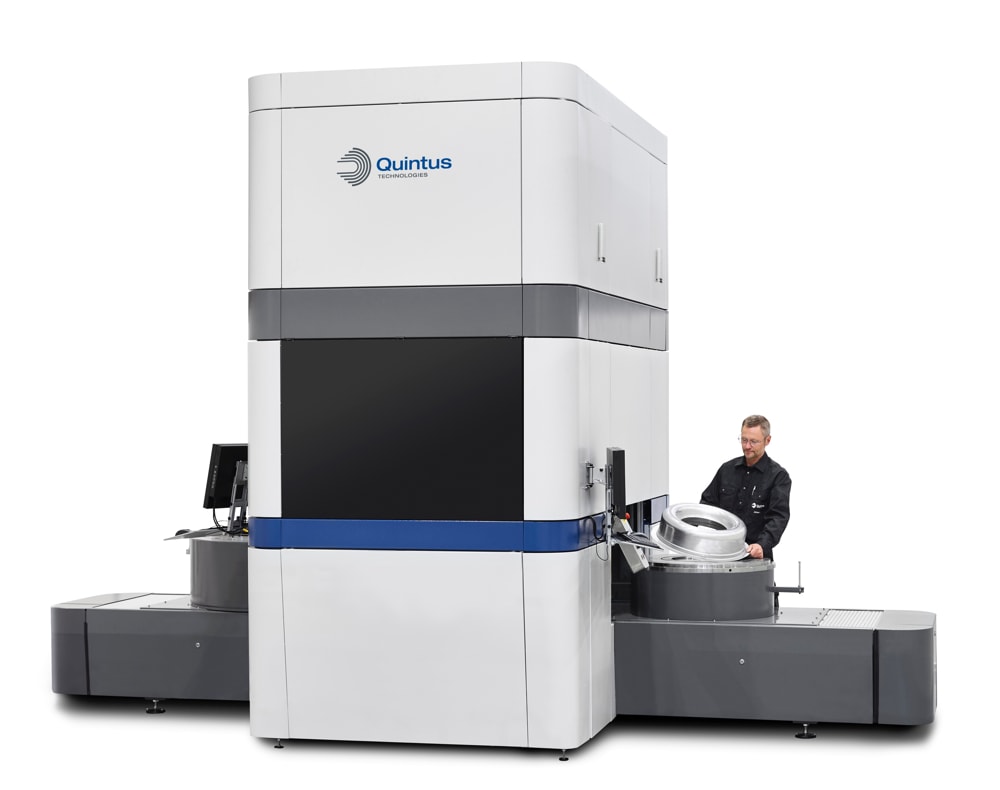

With the installation of two hydroforming deep draw presses from Quintus Technologies, F&B Manufacturing has elevated both the capacity and capabilities of its Phoenix, Arizona (USA) facility.

“The presses’ flexible forming technology allows F&B design and development engineers to offer more options to serve customer production streams, while also addressing new applications and markets,” the press specialist told ISMR.

“Producing complex shapes and assemblies has set F&B Manufacturing apart since we were founded in 1923,” said Brian Morris, F&B’s general manager. “Hydroforming is at the core of our success. Our two new Quintus presses replace decades-old hydroforming presses that did not fit with our expansion plans. With this investment, we are elevating our capabilities and partnering with a well-established OEM. We’re now in position to get the most for our investment for decades to come.”

Both presses are the Quintus model QFM 1.1-800 Deep Draw Press, featuring a modular dual-tray shuttle system that allows F&B to draw up to 10 inches (254mm) deep and accept blank sizes of up to 43.1 inches (1095mm) in diameter, a 25 per cent increase over previous capacity. Using high isostatic pressure up to 11,600 psi, parts can be formed in a variety of tough materials and thicknesses to tight tolerances with minimal thinning. Both presses offer the versatility to form with a programmable, movable punch, with the added capability to form with single-half cavity, block, and expansion tooling.

“Not only can we support larger parts, we have the flexibility of three forming operations in a single press, consistent with our goal of being a fully integrated supplier and a one-stop source for our customers,” said F&B sales manager, Misty Reynolds.

To cement this partnership, F&B supplemented its order with a long-term Quintus® Care Programme for application support, availability of spare and wear parts, and technical support. To further strengthen collaboration, F&B and Quintus also negotiated a promotional agreement where F&B is a preferred supplier for the cooperative advancement of hydroforming applications.

“F&B’s Phoenix facility is an excellent demonstration site for continuing R&D with Flexform technology and to showcase its versatile production capabilities,” says Ed Williams, General Manager – Americas, Quintus Technologies. “In addition, our companies will cooperate in joint marketing activities including trade shows, open houses and contract manufacturing referrals.”

For more information, visit https://quintustechnologies.com/ and https://www.fbmfg.com/