Sheet metal fabrication market

Submitted by:

Sara Waddington

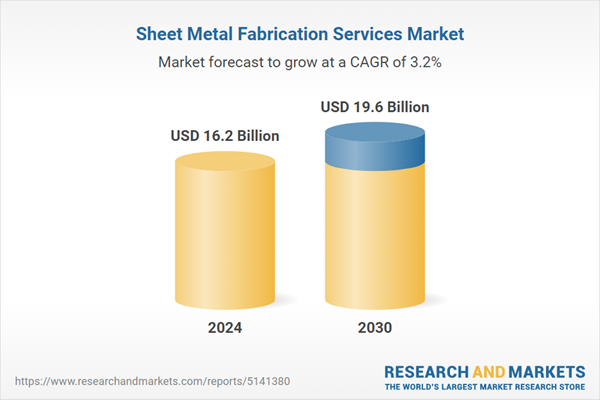

The "Sheet Metal Fabrication Services - Global Market Trajectory and Analytics" report was recently added to ResearchAndMarkets.com's portfolio. Amid the COVID-19 pandemic, the global market for sheet metal fabrication services is estimated at US$ 14.8 billion in the year 2020, according to the report. It is projected to reach a revised size of US$ 17.2- billion by 2026, growing at a CAGR of 2.6% over the analysis period.

“Growth in the global market is being driven by rapid urbanisation in many developing regions, and a robust trend of R&D investments in several services sectors. Increasing demand for sheet metal fabrication from a wide range of major end users such as military & defence; aerospace; automotive; oil and gas; industrial machinery; medical devices; construction; agriculture; consumer products and electronics is expected to drive growth,” explained the report.

“The current focus on enhancing operational efficiency and lean manufacturing is contributing to increased demand for the process of sheet metal forming among OEMs. Innovative prefabrication techniques adopted by sheet metal fabrication service providers to meet growing demand are expected to further drive the growth. The increasing shortage of labour could be addressed by adopting cobots in metal fabrication processes,” it added.

It highlighted the increasing number of metal fabrication facilities, which are adopting cobots to ‘enhance operational efficiency and improve product quality’ and the growing use CNC machine tools for several applications including moulding and shaping.

Steel, one of the segments analysed in the report, is projected to grow at a 3% CAGR to reach US$ 7.7 billion by the end of the analysis period (2026). Growth in the Aluminium segment is readjusted to a revised 2.5% CAGR for the next seven-year period.

“This segment currently accounts for a 38.9% share of the global sheet metal fabrication services market. Steel and Aluminium are the most widely used metals for sheet metal fabrication on account of their durability, high strength and corrosion-resistant properties. Steel is poised to continue making strong gains in the market, given its importance as a preferred building material in large-scale construction projects,” underlined the analyst.

“The sheet metal fabrication services market in the U.S. is estimated at US$ 2.7 billion in the year 2021. The country currently accounts for a 17.78% share in the global market. China, the world's second largest economy, is forecast to reach an estimated market size of US$ 6 billion in the year 2026, trailing a CAGR of 3.4% through the analysis period,” it added.

Among other noteworthy geographic markets are Japan and Canada, each forecast to grow at 1.5% and 2% respectively over the analysis period. Within Europe, Germany is forecast to grow at approximately 1.8% CAGR while the ‘Rest of European Market’ (as defined in the study) will reach US$ 6.2 billion by 2027.

“Due to growing demand in the Asia-Pacific countries, a number of companies are shifting their manufacturing base to this region and this, in turn, is boosting the region`s sheet metal fabrication services’ market growth,” concluded the report.

For further details, see https://www.researchandmarkets.com/r/jdj8md