Rise of the cobot

Submitted by:

Sara Waddington

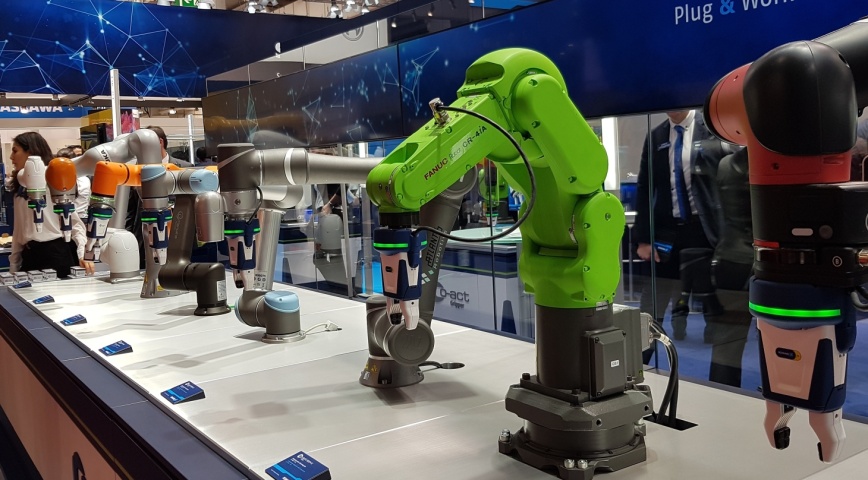

Robotics and automation are among the key technologies for ensuring lasting international success. Cobots interact directly with humans and give manufacturing companies a competitive edge in the market. At EMO Hannover 2019, from 16-21 September 2019, trade visitors will find various automation solutions and collaborative robots aimed at enhancing productivity.

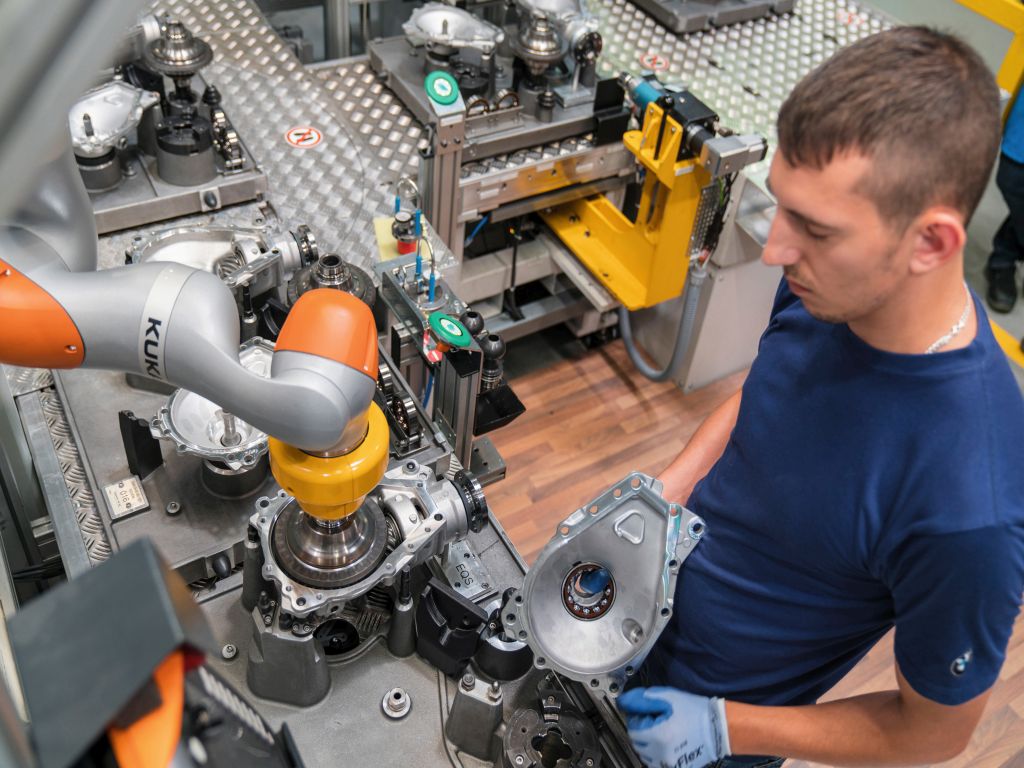

“Automation and digitalisation can be used to make manufacturing processes more efficient. Cobots are of particular interest. These collaborative industrial robots work together with humans – without special protective measures such as fences or demarcated areas. Robotics manufacturers, suppliers of various peripheral components for automation solutions, as well as safety and scientific experts, will be providing an overview of the current situation and giving forecasts for future developments at EMO Hannover 2019,” explained the show organiser.

"Humans are indispensable for intelligent production," says Jochen Vetter, Manager of Robot Safety, Pilz GmbH & Co. KG in Ostfildern. "Robots can perform physically demanding or repetitive activities, leaving the humans to take care of more sophisticated tasks. Automation can thus also provide a response to the demographic shift."

Different validation methods have to be applied to human-robot collaboration (HRC). For example, it is imperative that measurements are taken to determine the safety risks involved in any possible collisions. Pilz has developed its own method for this. A system measures the forces acting on the human body and compares them with the ISO/TS 15066 limit values for collaborative robots.

"The challenge is to eliminate any boundaries between the working areas of humans and machines. In addition to the dangers posed by the robot, human movements must also be taken into account," said the robotics safety expert. "The speed of these is not always predictable, nor are human reflexes or the sudden arrival of other people. Collisions, however, should never result in injury. These must be prevented by the use of more reliable control systems and intelligent, dynamic sensors built into the robot. In addition, it is important to set reliable safety standards based on normative principles.”

The interaction will develop 'organically', for example in terms of language and gestures, said Vetter. In addition, he believes that HRC solutions will, in future, be linked to the factory control system via OPC UA or Industry 4.0 RAMI standards. Potential areas of application lie not in large-series production, but in the manufacture of medium and small batches. HRC makes sense in situations where employees can be relieved – ergonomically – of physically strenuous tasks, such as in maintenance work.

"Collaborative and mobile robot systems offer new possibilities for the automation of machine tools. For the first time, automation can break out of its rigid constraints and achieve unprecedented levels of flexibility and productivity thanks to innovative robotic solutions," reported Peter Pühringer, Division Manager at Stäubli Robotics in Bayreuth.

Stäubli has designed its new six-axis TX2 generation for universal use. The robots in the new version can collaborate directly with humans. They are also available as mobile and collaborative robot systems.

Prof. Gunther Reinhart, holder of the Chair of Industrial Management and Assembly Technology at the iwb (Institute for Machine Tools and Industrial Management) at the Technical University of Munich also added: "Work is currently focusing on HRC planning support, on safety, and also on instructing the robots. Safety-related innovations are aimed at detecting possible collisions in advance through the use of different types of sensors – such as capacitive or ultrasonic sensors – or cameras.

“Once the legal issues of occupational safety have been clarified, collaborative robots are likely to be used mainly in assembly. Other major potential applications include ergonomic assistance. For this, however, there must first be more HRC robots which are capable of handling higher payloads. The Institute for Machine Tools and Industrial Management will be on hand at EMO Hannover 2019 to provide further information to trade visitors."

The principal focus of EMO Hannover is on metal-cutting and forming machine tools, production systems, high-precision tools, automated material flows, computer technology, industrial electronics and accessories. EMO Hannover 2017 attracted almost 2,230 exhibitors from 44 different countries, and around 130,000 trade visitors from 160 nations. EMO is a registered trademark of the European Association of the Machine Tool Industries, CECIMO.

Subscribe to International Sheet Metal Review to receive 10 magazines per year, packed with the very latest industry news and product reviews.