Slight recovery for German machine tool orders

Submitted by:

Sara Waddington

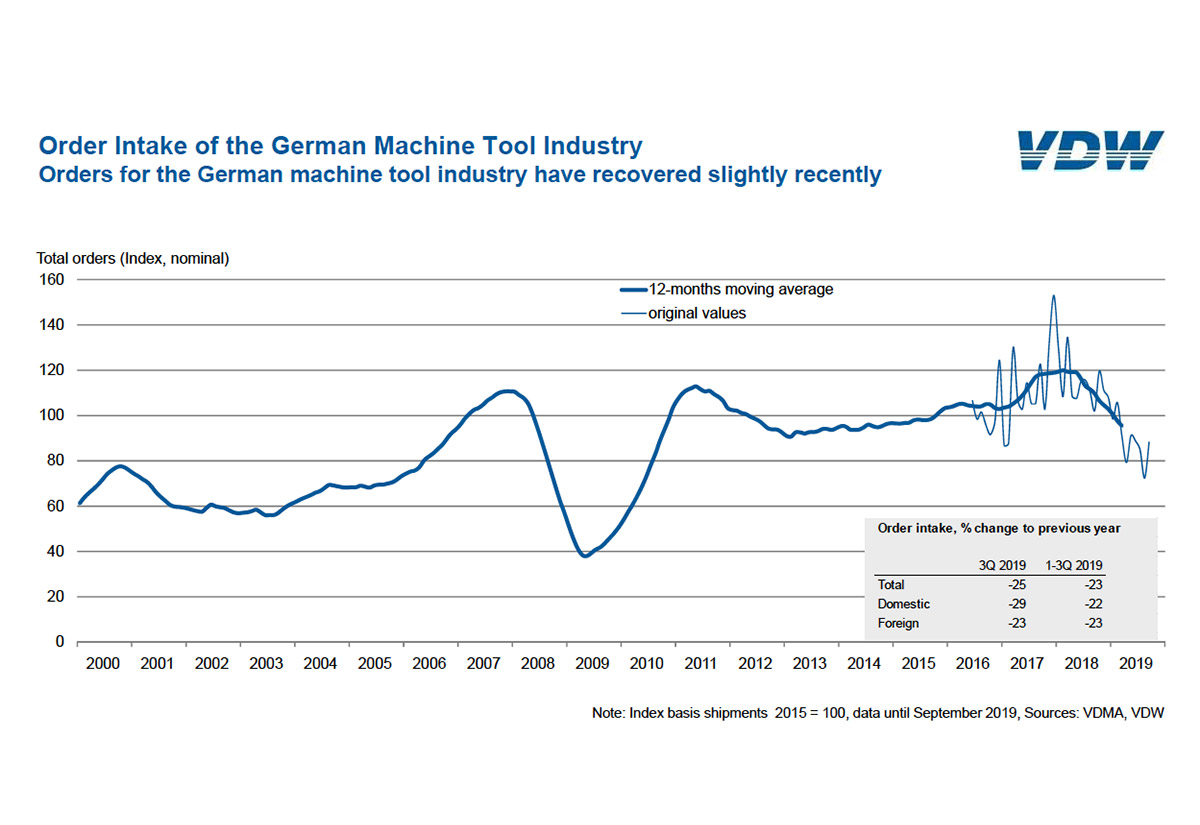

Header image: Order bookings in the German machine tool industry.

According to the VDW, orders received by the German machine tool industry in the third quarter of 2019 were 25 per cent down on the same period last year. Orders from Germany fell by 29 per cent. Around 23 per cent fewer orders were also received from outside Germany. Orders received fell by 23 per cent in the first nine months of 2019. Domestic orders were down 22 per cent in this period, with overseas orders 23 per cent lower.

"International demand for machine tools is continuing to decline, although the levels have recovered slightly just recently," said Dr. Wilfried Schäfer, Executive Director of the VDW (German Machine Tool Builders' Association), commenting on the results.

“Never before has the industry been confronted with such an accumulation of factors, all of which have had a negative impact on business: a cyclical downturn coupled with trade conflicts and instability in the largest customer, the automotive industry,” added the association.

Compared with the summer months, however, the volume recently stabilised somewhat for metal-cutting machines, which account for around 70 per cent of total production.

"We are seeing the first EMO effects here," said Schäfer. However, it remains to be seen whether this will stabilise in the coming months. Orders levels in forming machinery even rose again in September. Overseas projects, in particular, had a supporting effect.

“Overall, order levels from the Eurozone are a source of worry. These fell by well over 30 per cent in each of the three months of the third quarter,” added the VDW.

“Oxford Economics, our forecasting partner, does not expect any appreciable recovery in demand from Europe for the year as a whole. Asian business is also giving the experts cause to worry. The boost provided by U.S. financial policy is now dwindling, meaning that America is also set to become more challenging as a market. All in all, the international economic climate has deteriorated considerably and is holding back investment, even if the mood has brightened a little recently,” said Schäfer.

2019 production forecast

Against this backdrop, VDW has lowered its production forecast for 2019.

"In view of the sharp drop in orders in the current year, it will no longer be possible to maintain the predicted moderate decline in production," continued the VDW Executive Director. The association is now assuming a decline of four per cent, with this figure being supported by the clearing of the order backlog. The gradual stabilisation in demand, which was expected in the summer for the second half of the year, has failed to materialise. Capacity utilisation fell to 86.9 per cent in October, down from 87.9 per cent three months earlier.

"The real problem will come in 2020 when the backlog of orders has been cleared," said Schäfer. In the current year, there is no longer any real chance of building up a significant buffer. The anticipated recovery in demand in 2020 is also only likely to be moderate after the sharp fall. This is also reflected in the forecasts for international machine tool consumption. Following the decrease of more than four per cent in the current year, the moderate baseline scenario described here represents a best case scenario. The calculation of national currency rates of change is also having a stabilising effect.

The German machine tool industry ranks among the five largest specialist groupings in the mechanical engineering sector. It provides production technology for metalworking applications in all branches of industry and makes a crucial contribution towards innovation and enhanced productivity in the industrial sector as a whole. Due to its key role for industrial production, its development is an important indicator for the economic dynamism of the industrial sector as such. In 2018, with around 73,500 employees (annual average in 2018, companies with more than 50 employees), the sector produced machines and services worth 17.1 billion euros.