Stand reservation starts for EuroBLECH 2020

Submitted by:

Sara Waddington

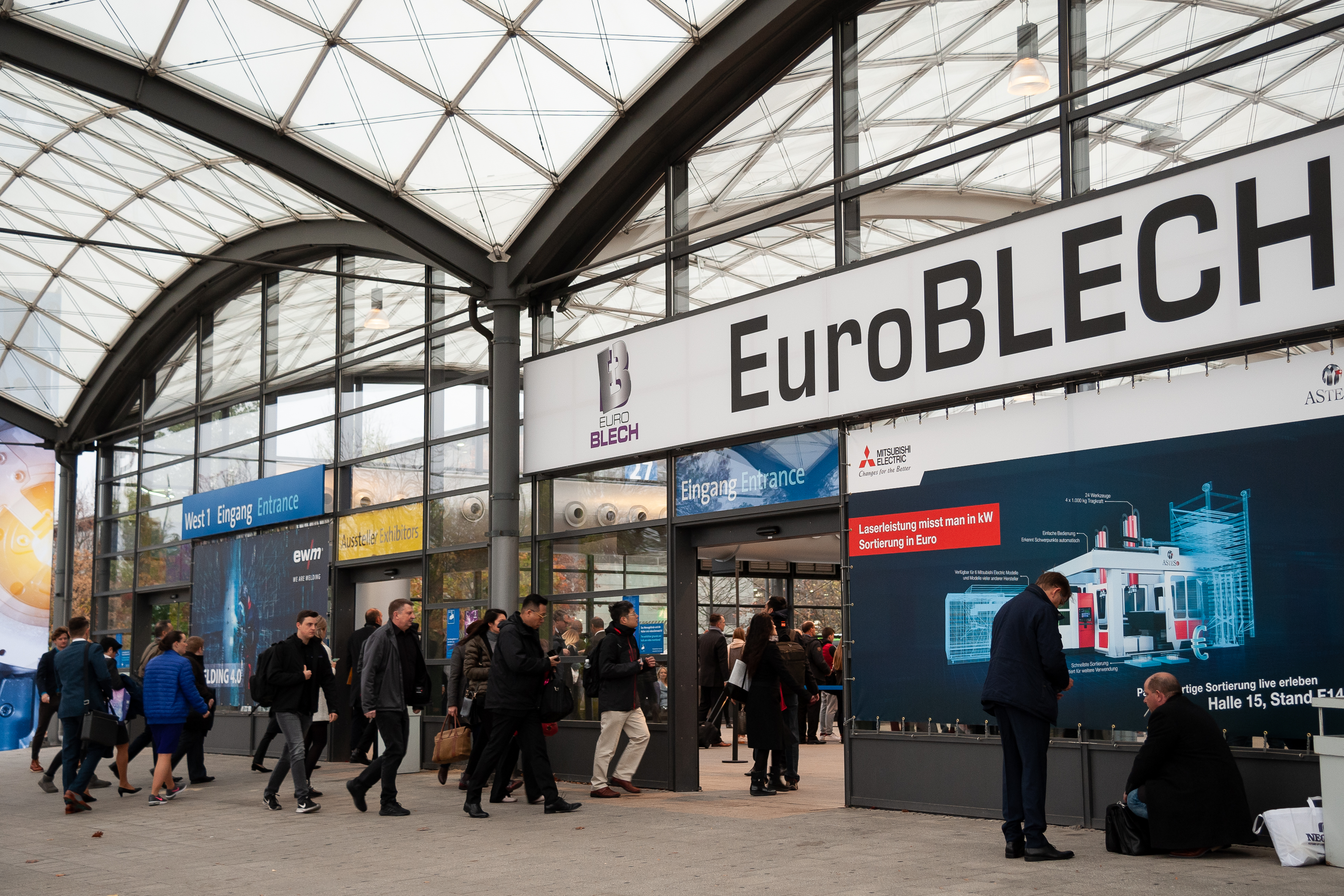

EuroBLECH 2020, the 26th International Sheet Metal Working Technology Exhibition, takes place from 27 – 30 October 2020 at the Hanover Exhibition Grounds in Germany. At the organisers’ offices of Mack Brooks Exhibitions, stand reservation has started. For the next exhibition, digitalisation of manufacturing processes, e-mobility and sustainable production as well as innovative materials are important topics.

“At the last EuroBLECH, the degree of digitalisation within the industry was already high. This was the starting point for the future of smart sheet metal working. Now it is time to firmly establish and optimise these digital production processes and enhance their efficiency and flexibility,” said Evelyn Warwick, EuroBLECH Exhibition Director, on behalf of the organiser, Mack Brooks Exhibitions. “At EuroBLECH 2020, manufacturers of machines, IT systems and tools for sheet metal working can present themselves to a global audience of visitors who are ready to invest. Visitors at the show are specifically looking for flexible and cost-efficient solutions to operate successfully in a competitive environment.”

“Almost sixteen months before the next EuroBLECH, we see a strong demand for stand space and are experiencing a high rebooking rate. The sheet metal working industry is in the process of dynamic development and innovative technologies are playing an important role. Therefore, exhibiting companies are interested in larger stand spaces this time to present a lot of new machines. We are therefore expecting a further growth in exhibition space for EuroBLECH 2020.”

The EuroBLECH exhibition profile is clearly structured and covers the entire sheet metal working technology chain: sheet metal; semi-finished and finished products; handling; separation; forming; flexible sheet metal working; joining; welding; tube/section processing; surface treatment; processing of hybrid structures; tools; machine elements; quality control; CAD/CAM/CIM systems; factory equipment and R&D.

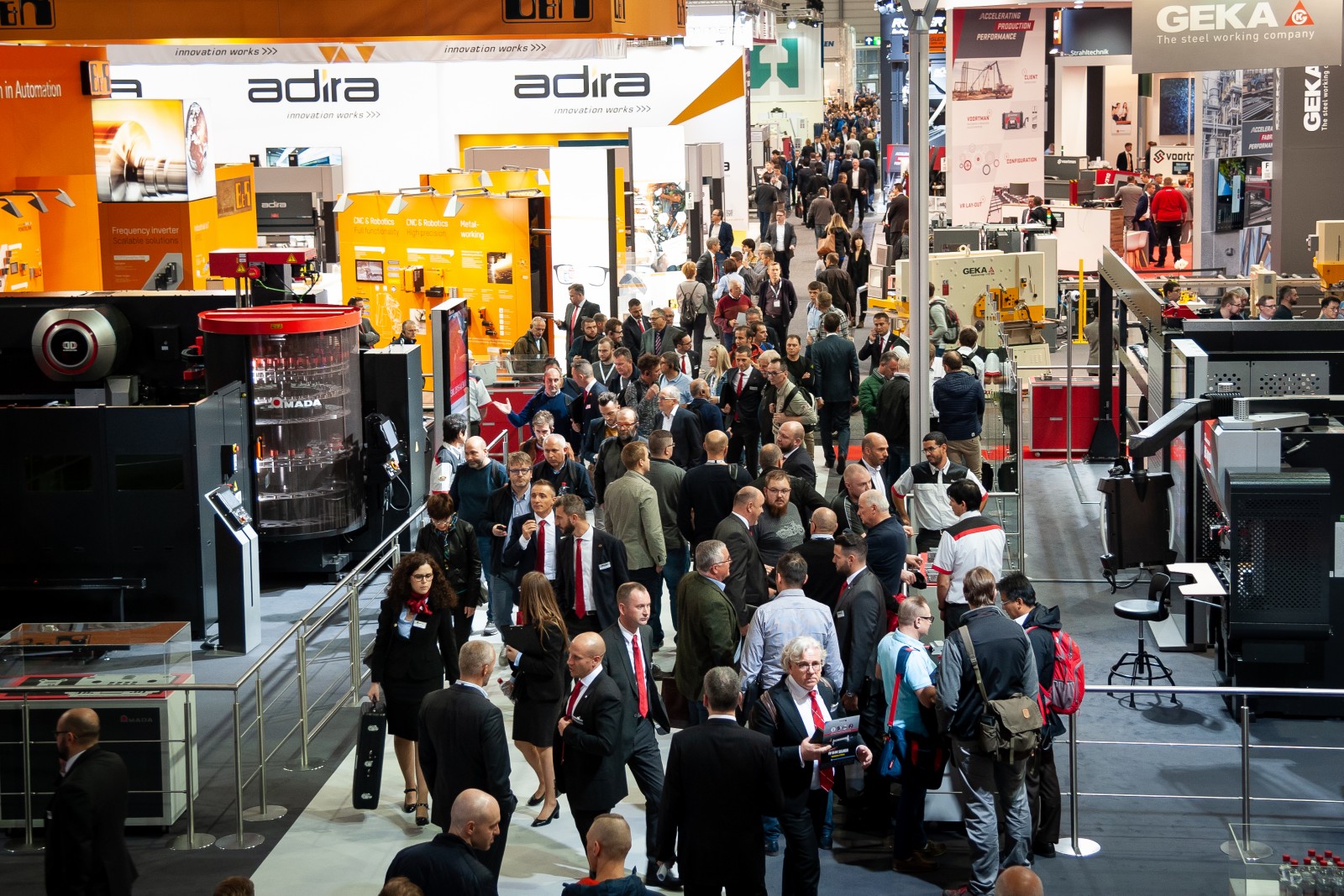

EuroBLECH 2018 ended last October with positive results: a total of 1,507 exhibitors from 40 countries, 89,800 square metres net exhibition space and more than 56,300 visitors from 105 countries. The general development towards digitalisation and Industry 4.0 in manufacturing was the predominant trend of the 25th International Sheet Metal Working Technology Exhibition.

“In addition to record net exhibition space, there was also an increase in internationalisation at EuroBLECH 2018 compared to the previous show: 58% of exhibitors at the show came from abroad, an increase of 4%. The biggest exhibitor countries, besides Germany, were Italy; China; Turkey; the Netherlands; Spain; Switzerland; Taiwan; Denmark; the USA and Austria. Around 49% of visitors travelled to Hanover from abroad to discover the latest solutions in sheet metal working, an increase in internationalisation of 10%. Traditionally, EuroBLECH attracts a high percentage of visitors with decision-making and buying capacity. At EuroBLECH 2018, 79% of visitors were decision-makers or involved in the buying process. Around 23,300 visitors came to the show with the definite intention of buying,” added EuroBLECH.

An exhibitor brochure, and booking form, is available on the show website at www.euroblech.com

Subscribe to International Sheet Metal Review to receive 10 magazines per year, packed with the very latest industry news and product reviews.