Volkswagen brand steps up pace of transformation

Submitted by:

Sara Waddington

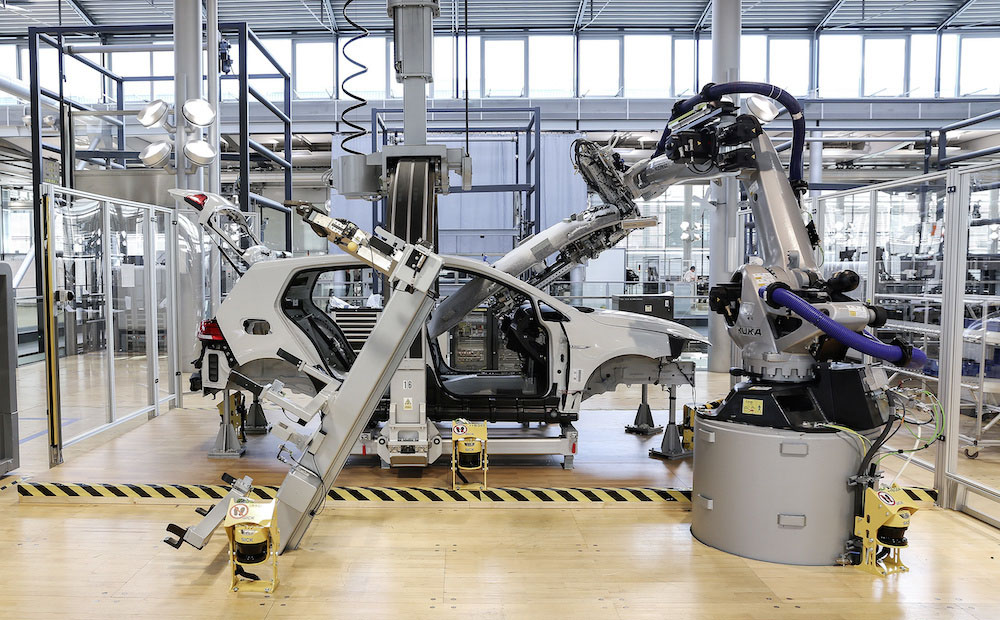

Header image: The headliner for the e-Golf is now being fitted by a robot, as standard.

April 2019

Volkswagen will be boosting the pace of its transformation following a solid fiscal year 2018. The brand is taking important steps this year to strengthen competitiveness on a sustained basis. This includes the start of the electric offensive, efficiency measures in production and further progress in productivity and margins.

At the same time, the brand is rolling out an earnings improvement programme aimed at achieving a sustained contribution of €5.9 billion from 2023. Measures include reducing complexity and optimising material costs. The programme is expected to gradually start delivering results in the period from 2019 to 2022. Furthermore, efficiencies in administration are to be leveraged by a stronger focus on process digitalisation. Efficiencies in administration are to be leveraged by a stronger focus on process digitalisation.

The current year will be a key year for the transformation of the brand. Investments in future topics totalling €19 billion will be ramped up through 2023. The aim is to undertake these investments using the brand’s own resources and to mitigate the rising costs of more stringent CO2 and exhaust regulations. That requires a sustained improvement in earnings of €5.9 billion per year from 2023. To that end, the Volkswagen brand is reducing material costs and the number of variants. Productivity at plants is to increase by five per cent per year. Increases in earnings and margins in sales are also planned.

Non-staff overheads and personnel requirements in administration are to be cut by 15 per cent each. The focus is increasingly moving towards digital transformation. Implementation of a digitalisation roadmap is designed to prepare employees for the digital world of work. Volkswagen will be investing €4.6 billion in IT systems to digitise administrative processes.

The company estimates that the automation of routine tasks will result in the loss of between 5,000 and 7,000 jobs by 2023. That can be absorbed, it said, by not recruiting replacements for employees who leave the company for retirement reasons. The potential number of employees born during the next three defined periods eligible for partial retirement totals about 11,000. Restructuring along the demographic curve is therefore possible. At the same time some 2,000 new jobs are to be created in Technical Development, which relates to electronics architecture and software. For all measures, Volkswagen has given its workforce a job security guarantee until at least 2025.

The brand, said Volkswagen, is making good progress with its second transformation towards a greater focus on e-mobility. In the next ten years, the brand will manufacture over 10 million electric vehicles based on the MEB, starting with the ID.

The Gläserne Manufaktur in Dresden is continuing to develop into the Volkswagen Group’s primary test location for trialling innovative technologies. In conjunction with its Wolfsburg and Emden factories, the Gläserne Manufaktur is part of a “technical centre” project. The main idea is to achieve automation of complex work steps within assembly.

“The special challenge is that testing and development takes place on an ongoing basis during production of the e-Golf in the Gläserne Manufaktur. The first project at the Dresden site is a world first – the headliner for the e-Golf is now being fitted by a robot as standard. This manufacturing step will also be used in production of the ID2 from the end of 2019 at our Zwickau plant.

The brand is targeting an operating margin in the range of four to five per cent for the current fiscal year. Despite the subdued economic outlook in key markets, further growth in sales revenue of up to five per cent is expected. Deliveries by the brand are expected to be on a similar level to last year, with momentum becoming increasingly positive as the year progresses.”

Volkswagen

Subscribe to International Sheet Metal Review to receive 10 magazines per year, packed with the very latest industry news and product reviews.