Innovate to accumulate

Submitted by:

Sara Waddington

Innovate to accumulate

Emmanuel Monnet, Alma’s CAD/CAM software department manager, outlines to ISMR how new software innovations, and Cloud models, will benefit manufacturers.

===

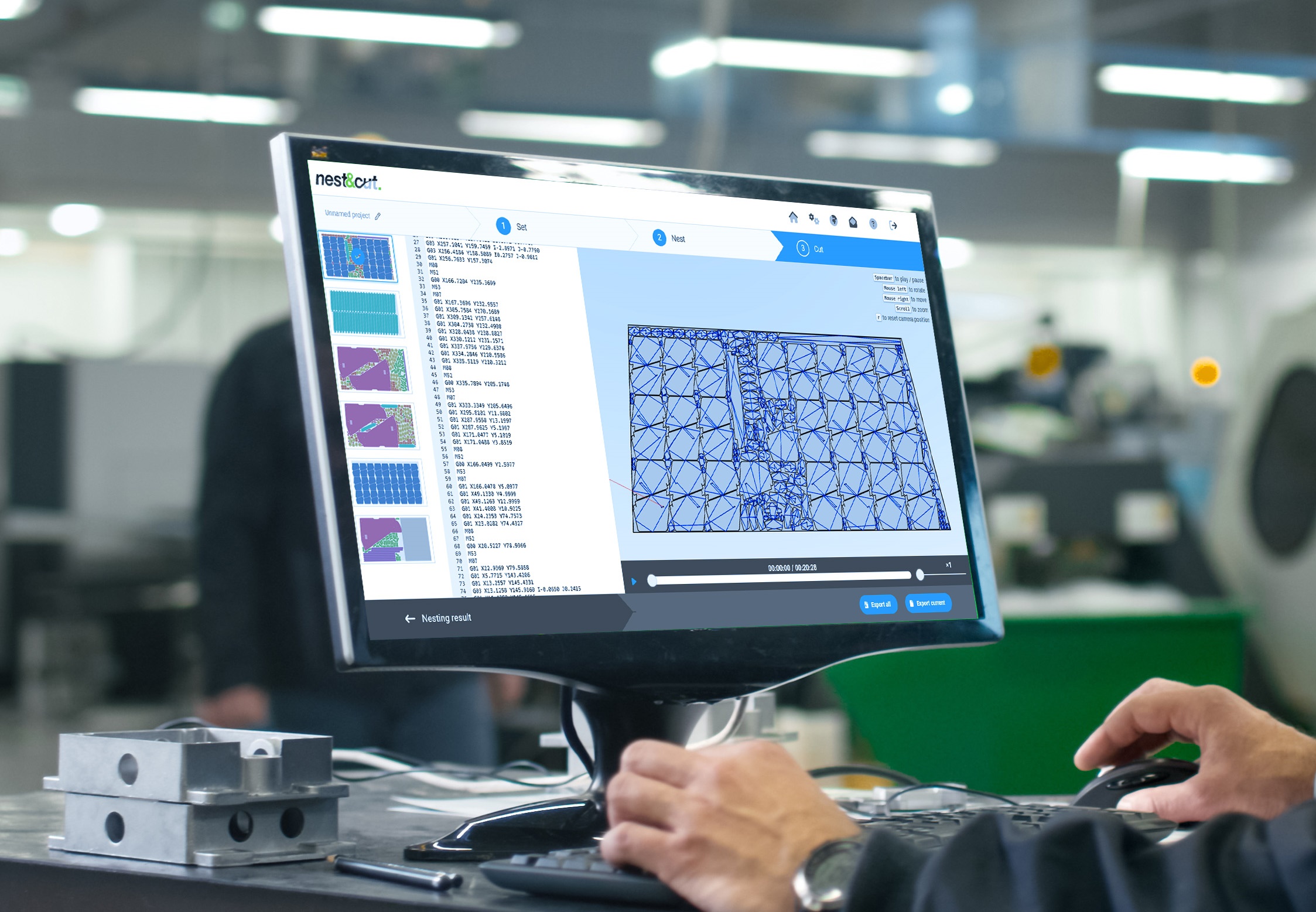

Alma is a leading developer of CAD/CAM software for sheet metal working, cutting and robotics. With over 40 years of experience in cutting optimisation and sheet metal CAM software, it is present in eight countries and represented in many other countries via its distribution network.

As a continuous innovator, around 30% of its turnover is invested in R&D every year. It offers a comprehensive range of CAD/CAM software for cutting in every form, sheet metal working and mechanical welding: cutting by fluid jet; punching; milling/routing; five-axis cutting; robotised cutting; cutting of circular and oblong tubes; folding/unfolding; robotised arc welding etc. These applications are completed by a set of modules centred on production management and control (quotes, planning) and integration into manufacturers’ information systems.

Its software products link CAD, ERP and workshops in the digital chain for sheet metalworking and machine welding, responding to the challenges of Industry 4.0. In parallel with the development of application software, it is also commercialising its cutting optimisation algorithms in the form of software components.

ISMR sat down with Emmanuel Monnet, Alma’s CAD/CAM software department manager, to find out how these new innovations will benefit sheet metal manufacturers now and in the future.

ISMR: Please outline any recent successes or achievements for Alma.

Emmanuel Monnet (EM): Despite a difficult economic backdrop, we have recorded significant growth since 2020 and our turnover is almost 20 million euros. Last year, we also reduced our carbon footprint by 9%.

Over the last few years, we have also seen additional positive indicators such as employee satisfaction (90% of our employees feel happy working at ALMA). Alma was created as a cooperative company (SCOP) in 1979. It is entirely owned by its employees. The cooperative status of the company has a huge influence on our corporate culture, which is based on values shared by all the employees: empowerment and accountability; mutual trust and solidarity; sharing of decisions and results; the importance of doing a good job; special attention paid to the quality of our customer relations etc.

Alma is also growing; we are always innovating and creating new products. We have hired more people in various roles across the company (R&D; sales and marketing; product development; support; services etc.) and will continue to do so. We have a leading position in the shipyard market and continue to grow in this market. We have attracted new sheet metal customers in North America and Europe and are working on new projects.

We have also signed several new contracts with machine-tool manufacturers for our tube software and see more opportunities and potential new projects in this area.

ISMR: What are your views on the current global business climate for sheet metal professionals?

EM: There is currently a market slowdown and, in some countries, sheet metal manufacturers no longer receive government subsidies to buy machine-tool technologies which has had an impact on the market. Some large machine builders are losing business and the machine tool market is contracting at the moment.

However, we also believe that there are opportunities for manufacturers to optimise their existing equipment and increase their productivity by using CAD/CAM software. We are an independent company that supplies software to end users, and our software can help manufacturers to optimise production so that they can produce more with less.

ISMR: Please explain your strategic/technical focus or vision over the next few years.

To read the rest of this interview in the May 2024 issue of ISMR, see https://joom.ag/Q1kd/p40