Press hardening line for India

Submitted by:

Sara Waddington

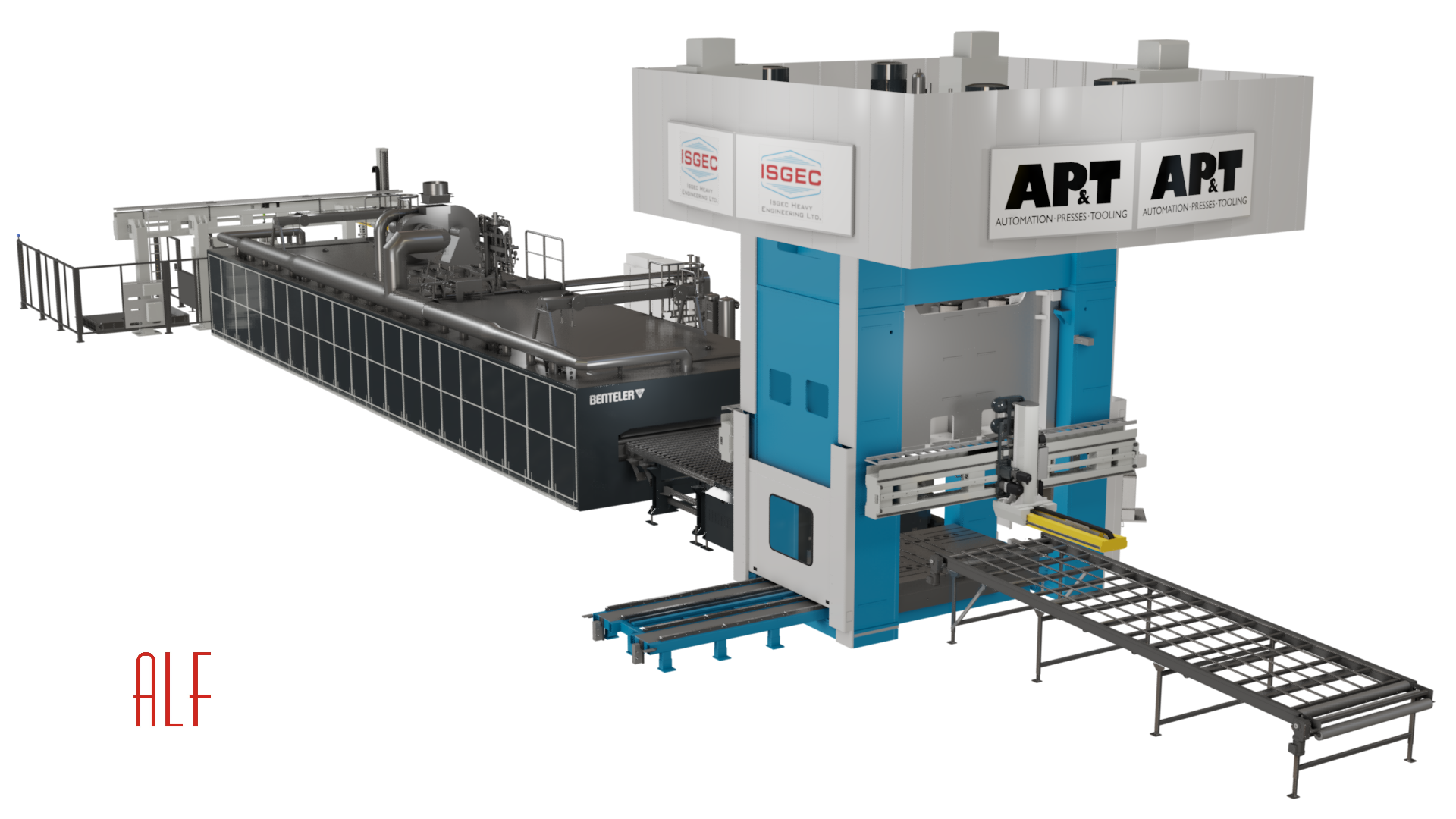

One of India’s leading manufacturers of chassis and hydroformed components for vehicles – ALF Engineering – has placed an order for a fully automated press hardening line from AP&T. This is AP&T's first substantial order in India, the fourth largest new car market.

“With over 125 installed press hardening lines the world over, we are a well-established partner to many actors in the global automotive industry. The ALF Engineering order enables us to take our next step into the important and growing Indian market,” explained Peter Karlsson, Area Sales Manager at AP&T.

Not only is the press hardening line AP&T's first in India, it is also the first for ALF Engineering.

“By investing in new technology, we aim to fulfill the emerging demands of our customers. ALF has proven itself in the past in our ability to identify, acquire, assimilate and productionise new technologies in a competitive environment. Press hardening is such an area of opportunity, which will create new revenue streams for our business,” said Koshy Ninan, Vice President of Business Development at ALF Engineering.

The new line provides automation, control systems and integration. The hydraulic press will be manufactured by the company’s Indian partner, ISGEC, based on AP&T's original drawings. The advanced roller hearth furnace concept, which is based on a modular design, will be provided by BENTELER Mechanical Engineering, a company with which AP&T has collaborated in several press hardening projects worldwide.

The new press hardening line will be installed in ALF Engineering’s new facility in KhedCity, near Pune (southeast of Mumbai), its thirteenth plant in India for manufacturing automotive components and assemblies. Delivery is expected to take place in the first quarter of 2022.

“Despite the ongoing pandemic, collaboration on this deal has been perfect. Since late 2019, all contact between us has been from afar,” Karlsson concluded.