Partners in progress: Volvo Cars and AutoForm

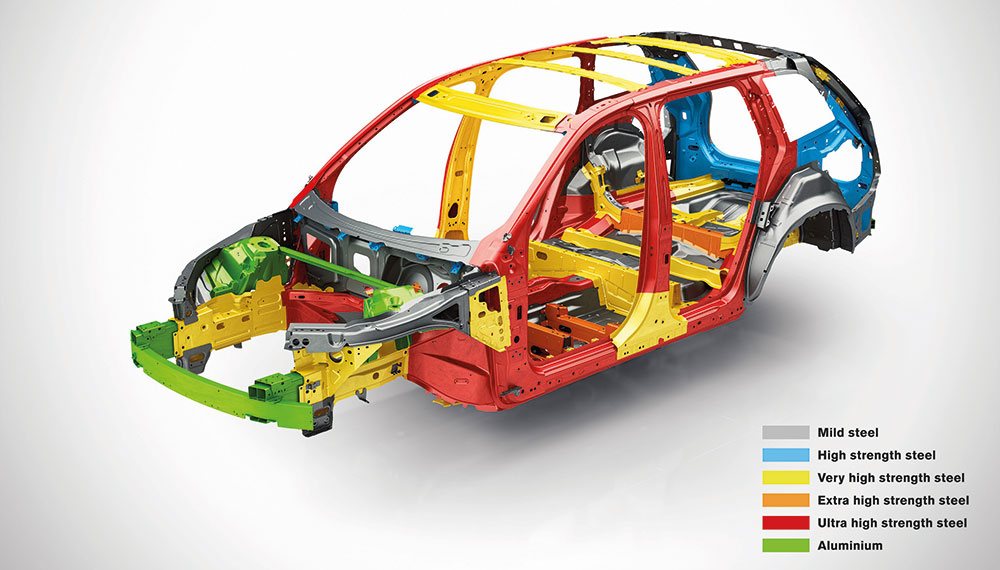

Header image: The XC90 has been made stronger by a more extensive use of hot-formed boron steel, which is the strongest steel presently used in the car body industry. The amount of hot-formed steel is around 40 per cent of the total body weight.

Simulated sheet metal forming operations have improved product quality, reduced body component lead time and married a more distinct, attractive design with improved manufacturability at Volvo Cars Body Components’ plant in Olofström, Sweden.

“ISMR visited Volvo’s plant at Olofström, 150km north east of Malmö, which produces more than fifty million car body components per year using AutoForm sheet metal simulation software.”

The first Volvo car rolled off the Gothenburg production line in Sweden in 1927. Since then, Volvo Car Group has been a byword for safety technology and innovation. In 2010, Volvo Cars was acquired by Zhejiang Geely Holding (Geely Holding). Today, Volvo Cars is one of the most well-known car brands in the world selling 642,253 cars in 2018, the company's fifth consecutive year of record sales. The largest market, China, represented some 20 per cent of total sales volume in 2018, followed by the United States (15%), Sweden (10%), the United Kingdom (8%) and Germany (7%).

Volvo Cars produces premium-segment car models in three versions: sedans (S60, S90), versatile estates (V60, V90) and SUV vehicles (XC40, XC60, XC90). Sheet metal forming simulation software, from AutoForm Engineering GmbH, has been instrumental in stamping and forming processes at its 291,314m2 plant at Olofström (Sweden), 150km north east of Malmö, which produces more than fifty million car body components per year.

ISMR was invited to visit its plant at Olofström to meet Volvo Cars' sheet metal experts on forming, testing and simulation. The production of body components has been located in Olofström (Sweden) since 1927 but the high-tech factory celebrated its 275th jubilee in 2010 (it started in 1735 as a blacksmith's mill). With around 2500 employees, the Olofström factory is a high-tech manufacturer of body panels for all Volvo's car models and also delivers to external customers such as Volvo Trucks.

An eye on sheet metal

At Olofström, the operation focuses solely on core business – panel pressing, engineering, die manufacturing and sub-assembly of body parts. Expertise in the shaping and joining of steel body panels has grown immensely strong in Olofström over many years and is the key to its success. It has developed a strong and stable partnership with AutoForm Engineering GmbH on sheet metal simulation software, using several AutoForm modules to simulate sheet metal forming and stamping processes, in its factories worldwide.

Volvo Cars' stamping CAE department, which numbers ten people (dedicated to simulation and related activities), is the nerve centre for stamping and stamping-related issues at Volvo Cars. Volvo Cars Manufacturing Engineering Stamping at Olofström has, with the smart use of metal forming simulation techniques, improved the manufacturability of Volvo Cars' distinctive design and reduced costs and part lead-times.

Volvo Cars Manufacturing Engineering uses AutoForm CAE software for draw-die development/optimisation, layout of trimming and flanging tools, detection of surface defects, prediction and compensation of springback, optimisation of material usage etc. Pre-production work includes die development, simulated forming, analysis and the manufacture of die sets for large and medium-sized tandem/transfer presses. A lot of dies are analysed to support all the new car models in production.

From 2000, with major changes in its workload and multiple projects on hand, it made the decision to just use AutoForm software for sheet metal forming. The entire AutoForm solution has allowed Volvo Cars Body Components to perform more accurate simulations, analyse more parameters and ensure many more loops and robustness evaluations.

"We need to be innovative and find answers to new challenges. We also need to be nimble and able to adapt to different challenges," Mats Sigvant, Technical Expert, Forming Simulation, Volvo Cars told ISMR. Mats works in the advanced engineering department, working closely with the CAE department and advising on aspects of friction testing, simulation and sheet metal material properties.

"We are also carrying our simultaneous engineering for Volvo Cars parts for Asian and U.S. suppliers, not just Volvo factories in Sweden, and manufacturing dies for Volvo Cars press lines in China. The part must be feasible to produce in any Volvo factory in the world. That’s a big change for us in terms of ways of working, as well as being very challenging, but it has worked quite well. It is a new way of thinking – it's about readiness for production anywhere and forward thinking. Last year, we passed 600,000 cars and our 2020 target is 800,000 cars. Our sales have increased and we have gained market share but quality and safety are still the over-riding principles of our operation here," he continued.

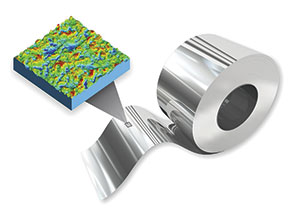

TriboForm modelling

Mats is working on a new friction modelling project using AutoForm's TriboForm software, which has changed his perspective on how to look at simulation results. Two things have a huge impact on results – one is material properties and the other is tribology. Friction, he says, is 'a can of worms'. TriboForm is software for the simulation of friction and lubrication conditions. Through a more realistic consideration of tribological effects, a new level of simulation accuracy can be achieved.

"The quality of sheet metal formed parts is strongly dependent upon the tribology and friction conditions that act during the forming process. These friction conditions are then dependent upon the tribology system i.e. the applied sheet material, coating and tooling material, the lubrication and process conditions," explained Mats Sigvant.

Marc Lambriks, General Manager, AutoForm Engineering Netherlands, explained why this is important.

"Current trends are geared towards lightweighting and they bring challenges. The use of thinner but stronger materials is challenging for general formability. However, forming thinner sheet materials is also more dependent upon friction and tribology for the final quality of the part. Therefore, what we are seeing is a movement where tribology and friction is becoming more relevant for accurately simulating the forming of those parts," he told ISMR.

"The goal of utilising TriboForm in Volvo car projects is twofold. First of all, the aim is to apply the TriboForm models on dies in early die engineering The motivation is that the majority of the forming simulations are performed to secure the die tryout i.e. solve as many problems as possible in forming simulations before the final design of the die and milling of the casting. Secondly, the aim is to study the effects on stamping results of new lubricants and sheet metal coatings."

"The quality of sheet metal formed parts is strongly dependent upon the tribology and friction conditions that act during the forming process."

Volvo's CAE team benefits from toolroom and production facilities that are close to its operations. Software results need to be tested and tryout is central to develop a large statistical pool of data.

"The problem with friction depends upon the surface of the sheet, the coating on the sheet, the amount of oil, the status of the die, the speed of the press, temperature etc. So, you can have one result in the toolroom and another on the line. We need to make the die work in trials and production, so it’s also about robustness. On the steel side, we have used DP800 (dual phase) grades for a long time (our mainstay for the cold formed, high-strength steels)," added Mats Sigvant.

A strong partnership

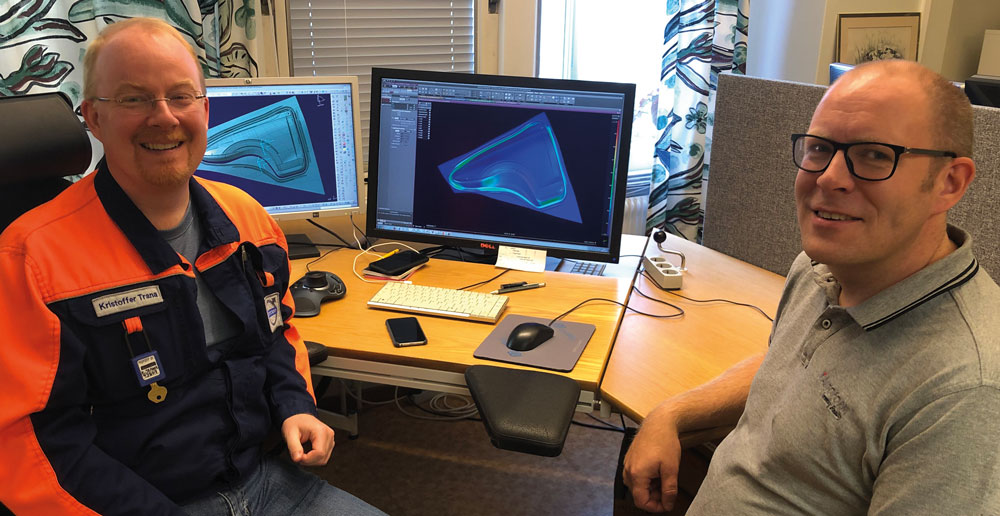

"Early on, when the first part surfaces are being designed, is where we start. It is a long period of simultaneous engineering work. This is basically done for all outer skin parts, hang-on parts and (sooner or later) for small body in white (BIW) parts. It starts with 'do we have a split-free process or wrinkle-free process?’ Early on, we want an accurate simulation reading and accurate process because we want to establish feasibility. We ask ourselves whether this part can be manufactured and which process will suit," Kristoffer Trana, Technical Expert, Stamping Feasibility, Volvo Cars, explained.

"We worked with AutoForm software from the earliest development phase. Later, we decide whether to manufacture the dies in-house or purchase them. Part geometry and springback are important issues to get the most out of the die without too many correction loops. If we purchase dies, we transfer our simulation (as it is our production intent) and the supplier carries on refining and updating the contents which are finally signed-off by us to enable the start of die manufacturing. If we manufacture the dies in-house, we just continue our work but on an even more refined level.

"Tryout gives you the correct feedback and you continuously develop your skills and knowledge. We may need to correct and improve the simulation. We can sometimes work with a part (e.g. a fender) for two years (from the earliest SE work to final simulation during die manufacturing) if we produce the dies in-house."

Die face design is a key part of that process and Volvo has built up considerable expertise in this area over the years.

"From a die face design perspective, we consider formability and how to design a part, and define the stamping process, to obtain a low level of springback. Do we need to make changes in the process for fewer cracks and wrinkles, or to get the best geometrical outcome? Sometimes, we need help from part design to facilitate this. We often do part compensations with the AutoForm software to check if the part is feasible for compensation (rather than for cracks or wrinkles). So many parts are difficult to produce today, so this is key. It is crucial to choose the right process at an early stage. Car body electrification is now a consideration; it sets new requirements for the floor architecture (including battery enclosures) and poses new stamping challenges," added Kristoffer Trana.

Volvo collaborates continuously with AutoForm and provides strong feedback to the software specialist, running development projects together such as a recent one using AutoForm-ProcessDesigner for CATIA (a CATIA workbench).

"We see Volvo as a strategic partner and we learn from each other. The ProcessDesigner for CATIA project sprang from Volvo's desire to bridge the gap between simulation and CAD. We recently added the option to compensate for the CAD surfaces (also a Volvo request) and to prepare the CAD models for NC machining. The software has been adapted to Volvo's needs and we have managed to work Volvo's way and match Volvo's approach to projects which, in the end, provides a real benefit for all our users," added Marc Lambriks of AutoForm.

The compensation option enables the user to effectively use springback simulation results to compensate the forming tools accordingly. The options for NC preparation enable the user to modify the designed CAD surfaces for milling. Both options were applied in the forthcoming Volvo Cars BEV model.

"It is important for us to be able to help Volvo streamline its overall workflow – AutoForm software helps it to do that."

Streamlining workflow

Volvo has been an AutoForm customer for 22 years. It currently uses AutoForm software for the engineering of manufacturable sheet-metal parts; estimation of tooling costs early in the planning and bidding phase; simulation-based process engineering; springback compensation; rapid creation of high-quality CAD surfaces; simulation of hot forming and quenching processes as well as to ensure robust manufacturing. Volvo is also working extensively on progressive dies and, over the last two or three years, has worked a lot with AutoForm's TriboForm software (virtual tribology modelling to better predict friction in the die).

"It is important for us to be able to help Volvo streamline its overall workflow – our software helps it to do that. We have a very strong partnership with Volvo. As a software company, we benefit from all the input we get e.g. regarding the modelling options in our software, the daily usage in a productive environment and the accuracy of our solution. We benefit from the testing that Volvo does and we appreciate this type of interaction and feedback on our software. As a partnership is always two ways, Volvo benefits from our collaboration through active participation in projects and involvement in developments. Such collaboration helps us to develop future versions of the software," added Marc Lambriks.

"The most powerful thing about AutoForm software is that it takes away much of the pain of the classical finite elements and lets you work with the creative stuff to think how to manufacture the part and determine the process (and not worry about how to do the simulation). This is quite important," explained Kristoffer Trana.

"We work on stamping simulation for every Volvo model across the range, regardless of where it is produced. We also do the manufacturing engineering process for every model, including the newly released Polestar electric model. We make dies for selected parts in almost every car model.

We also do dies/SE for all models (manufacturing engineering processes + simulation = simultaneous engineering or SE). Safety is fundamental to Volvo – it is our number one consideration and is in our DNA."

Coping with complexity

"Generally, very often what is beneficial for formability (cracks and splits) can be counter-productive for springback. You have to find a balance. Our advanced engineering departments have considered higher formability materials. You may need to use a different process. We have improved over the years but demands on us have also tightened. We have reached a point now where we should continue with the simulation but you have to look at the overall process of developing the car. It needs to be tightened up. You cannot have late changes or late decisions on suppliers or processes. We need the right input to get an accurate output. A late material grade change can cause massive problems. The process is complex – changes can produce unexpected results so you must have a reliable model to be able to accurately predict what will happen," Mats Sigvant pointed out.

"Volvo is one of the most advanced automotive users of simulation and has a deep understanding of the technology behind it."

Safety and lightweight materials sometimes exhibit slightly peculiar behaviour that needs to be understood. Volvo is one of the most advanced automotive users of simulation and has a deep understanding of the technology behind it. It also applies it for academic research. This is particularly important when it comes to Industry 4.0 and digital twin applications for the future.

"The structural behaviour of the press and die can also influence the simulation result, especially to make milling data compensations in time. We have many different cases where failure evaluation methods need to be improved. We need to decrease the time spent on making die sets etc. It takes too long to simulate/model the complete process, on the CAD side, and more needs to be done, faster. AutoForm-DieDesigner helps us to do this in certain applications for simultaneous engineering work. This saves us a huge amount of time (probably 50% or more of time) for geometry creation. The exception is for press hardening dies, where we mostly need to do the CAD," added Kristoffer Trana.

"Just a year ago, we were CAD modelling progressive dies. Now, we use AutoForm DieDesigner ProgDie software for the die modelling. We can make quick decisions and be flexible," he continued.

Volvo is currently working on electrification and self-driving (AD) cars. Electrification has had a significant impact on part design. Hybrid platforms/architecture are also a challenge. Volvo has also been inventive when joining aluminium to steel, press hardened or mixed metal parts.

"We are trying to shorten the total time it takes to develop a car and produce it. So, we are also introducing more things into the simulation to detect more problems and shorten the manufacturing time of the die and ensure that the process is robust. It’s about coping with complexity," explained Mats Sigvant.

An eye on accuracy

"Geometrical accuracy of the part is a challenge and it needs to be successful every time. We have reduced the number of quality loops on the dies, as a result. Simulation helps us to bring it down, but we need to bring it down further (repeating this exercise in the toolroom). We cannot make dies for specific press lines or presses – you never know where the part will be produced – so robustness in the design is key," underlined Kristoffer Trana.

Although Volvo has streamlined product and process designs, elements in the process have changed such as tolerances and stronger materials (like aluminium). Industry 4.0 will place even higher demands on accuracy.

"Our productivity figures are competitive, and that is largely thanks to the simulation."

"In terms of Industry 4.0, as a simulation company we aim to completely digitalise the metal forming process chain. With the release of AutoForm-TryoutAssistant, we try to bridge the gap between the engineering department and the tooling room. Another step in digitilisation is our development towards virtual assembly (springback is an issue when you have narrow tolerances) – this is also part of Industry- 4.0 so that parts are right first time with full digitilisation of the process. We are just starting on this ladder," explained Marc Lambriks.

"Our productivity figures are competitive, and that is largely thanks to the simulation which have laid the foundation for robust processes. Stamping engineering is an iterative process – you change the process, you change the part. Every part is unique. Part price is also important, as is investment – much depends upon the volume. We are involved very early in the car development process – stamping is always very early in the process. As soon as we have CAD models, we start working. There may be several design models at this stage," added Kristoffer Trana.

A tour of the tool room

ISMR was given a tour of the tool room at Olofström – this is a key part of the process, where dies are manufactured and tryout processes can prove, or disprove, simulation results. To avoid logistics costs, more than one part can be made from one die set with adjustments to the die. Some car models share some parts.

"Volvo aims to produce as many parts as possible from the same die and same set-up."

"The moulds for small and large structural parts are made here and delivered to Volvo car plants across the world. We produce a wide range of parts from draw dies (the smallest die is 2.5m long, up to dies that are 5m x 2.8m long). You will see very large dies in the tool room here. The projects that you see in the machine area are running projects (on large structural parts) which help us to learn about high-strength steel forming in-house. This is an important project for simulation development. You need to have the right die materials, as there is a lot of wear, so we use steel block materials in the dies," explained Johan Nedemo, Manager, Die Process Engineering Team.

"It has been a great learning experience for us (we processed almost 1000 steel blocks needed to increase our efficiency). We have also invested in three new NC milling machines over the last three years, as well as a very large milling machine for the larger dies."

There is constant demand for new dies, as production press lines have grown bigger. From a cost perspective, Volvo aims to produce as many parts as possible from the same die and the same set-up.

"As a die manufacturer, we have to adapt to that and invest more in bigger presses for tryout, larger milling machines and bigger overhead cranes for lifting. We are in the middle of this investment period. When you have big 5m dies like this, it is not a stable environment. The die half weighs 20 tons but it still flexes, so we needed to change the shop floor and insert flat steel bars to support the dies, which can rest on the floor, so that there are no trim gaps and the cam adjustments are accurate etc. At the moment, we are digging a press pit for a new press that we have ordered. Our plan is to make further modifications over the next three or four years. It is a real challenge to adapt to the die sizes,” continued Johan Nedemo.

"The greatest challenge is to shorten the lead times and deliver dies on time for the tryout and we work with Kristoffer’s CAE department to do the theoretical work on compensations and milling data. We want to avoid hard geometry loops and the milling data must be done to ensure as short a lead time as possible for the manual grinding in the dies. So, we need to mill the dies in the best possible way, with contact in the right places, and reduce manual grinding so that the contact between the die and the blank are in the correct position."

The ultimate aim is to have almost no spotting in tryout, giving a result with a dimensionally accurate part. This is what Volvo aims to do, learning from project to project through simulation and more.

"Four or five years ago, we used to do compensations (mainly on the draw die). Now, we try to do individual compensations in all the dies to ensure that the part lays stable on the lower die all the time, otherwise we will deform the part when we close the dies and lose control of the part quality," added Johan Nedemo.

Today, Volvo Cars carries out a mixture of simulation but also physical scanning of the part from the previous die. In the future, it aims to use mainly simulation, with not much part scanning. It uses scanning now to evaluate if the simulation is correct - the best time to do that is when it manufactures the dies and it looks the same as in the simulation. It is important to carry out the simulation and die manufacturing activities side-by-side as they complement each other.

"For simulation compensations, our target is within +/- 0.5mm correct from the nominal, which is quite hard. If there is a mismatch between part and simulation (maybe 1mm off), we need to investigate which corrections need to be done in the simulation. Small adjustments can make a big difference. Accuracy is everything. Die manufacturing simulations must be accurate or everything is affected. This calls for a high level of skill and experience. A delay on one project can seriously affect the next die manufacturing project," concluded Kristoffer Trana.

"The ultimate aim is to have almost no spotting in tryout, giving a result with a dimensionally accurate part."

Into the future

Volvo Cars has announced new financial and operational ambitions designed to position the company as a leading player in the global automotive business by the middle of the next decade. On the operational side, it expects to generate half of all sales annually from fully electric cars, one third of all cars sold to be autonomous driving cars and half of all cars it offers to customers from its subscription service.

It expects these initiatives to transform its connection to its customer base, with the aim of building a total of over five million direct consumer relationships by the middle of the next decade, creating new sources of recurring revenue. This will also offer the company far greater potential to develop connected and other services for customers.

“Our customers’ expectations are changing rapidly. This means that Volvo Cars is also changing rapidly. These initiatives will help transform Volvo from being purely a car company to being a direct consumer services provider,” said Hakan Samuelsson, President and Chief Executive, Volvo Cars.

On the financial side, Volvo Cars aims to generate premium level profitability in line with other premium car makers, driven by increased sales and revenues across all three global sales regions and a broader range of cars including sales to the new segment of autonomous ride-hailing companies. The company’s improved financial performance will also be driven increasingly in the future by industrial synergies generated with its affiliated partner companies.

Volvo Cars expects to benefit from lower procurement costs, shared development costs and economies of scale alongside Polestar, its premium performance electric car brand.

Simulation will play an important role in helping Volvo to reduce its costs, maintain its quality standards and make the required economies of scale to achieve this vision.

For further information, please visit AutoForm's website.

Subscribe to ISMR for free and receive 10 digital magazines per year, packed with the very latest industry news and product reviews.

Recent comments